-

-

ADVANCED PYROLYSIS TECHNOLOGYFOR CIRCULAR ENERGYAND SUSTAINABLE FUELS

ADVANCED PYROLYSIS TECHNOLOGYFOR CIRCULAR ENERGYAND SUSTAINABLE FUELS

PYROCY is derived from “pyro”, referring to thermal transformation, and “cy”, inspired by cycle and circularity. The name reflects a technology that does not burn, but reforms materials into new value streams. PYROCY represents a closed-loop approach where waste re-enters the economy as fuels and raw materials. The brand stands for circular innovation, resource recovery, and a new cycle for materials that were once considered waste.

Turning Waste into Energy Value

PYROCY develops and deploys advanced pyrolysis solutions designed to convert waste streams into usable energy, fuels and valuable by-products. Our technology enables industries and municipalities to close the loop of materials, reduce environmental impact and generate new revenue streams from waste.

Built on solid engineering principles and real operational experience, PYROCY systems are designed for reliability, efficiency and long-term performance.

Every year, hundreds of millions of tons of plastic waste and over a billion end-of-life tires are discarded worldwide, often into landfills or low-value uses. Landfill restrictions, recycling mandates, and demand for circular feedstocks are creating a structural pull for new waste-to-fuel solutions.

Pyrolysis oil is now a strategic feedstock for refineries, crackers, and industrial burners, with growing demand from low-carbon fuel and chemicals markets.

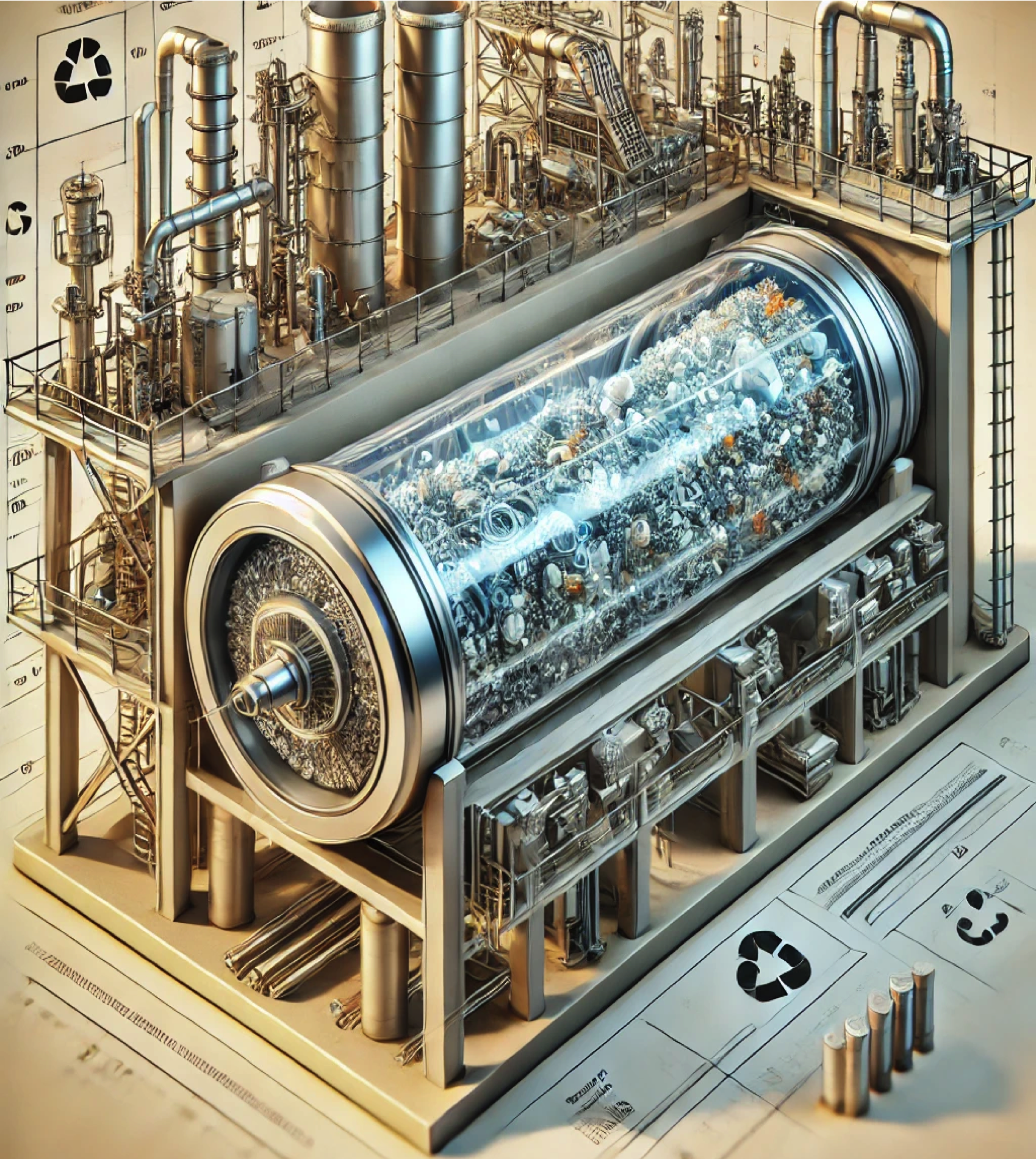

ADVANCED PYROLYSIS PROCESS

FEEDSTOCK FLEXIBILITY

Designed to process a wide range of waste materials, including plastics, tires, biomass and industrial residues.

CONTROLLED THERMAL CONVERSION

Precise temperature management ensures stable operation, high conversion efficiency and consistent output quality.

VALUABLE OUTPUTS

Production of pyrolysis oil, syngas and solid by-products that can be reused as fuel, energy or industrial inputs.SOLUTIONS

PYROCY offers modular and scalable pyrolysis systems adapted to different project sizes and waste volumes. Our solutions are engineered for industrial environments, focusing on safety, operational continuity and ease of integration.

Modular and scalable plant design

Industrial-grade materials and components

Designed for continuous operation

Optimized energy recovery

Compliance-ready architecture

APPLICATIONS

CIRCULAR ECONOMY INITIATIVES

Closing material cycles and reducing landfill dependency.

MUNICIPAL & REGIONAL SOLUTIONS

Supporting cities and regions in sustainable waste treatment strategies.

WASTE-TO-ENERGY PROJECTS

Converting waste into electricity, heat or usable fuels.

INDUSTRIAL WASTE MANAGEMENT

On-site or centralized treatment of industrial residues.

WHY PYROCY

PYROCY combines technological expertise with a practical, project-driven approach. Our focus is not only on innovation, but on delivering systems that perform reliably in real-world conditions.

Most solutions are either oversized, bespoke refineries or small, isolated units with limited integration. PYROCY focuses on **modular, replicable micro-refineries** that can be deployed close to waste sources, aggregating capacity through multiple standard 15–120 TPD units rather than single mega-plants.

Our objective is to unlock local waste streams and convert them into globally tradable, low-carbon liquid fuels.

Industrial and scalable design

Focus on operational stability

Long-term performance mindset

Alignment with environmental and circular economy goals

VALUE PROPOSITION

PROVEN TECHNOLOGY Industrial Track Record

MODULAR European Manufacturing

DUAL FEEDSTOCK

High Yields · Low OPEX

VENTURE-READY Partnership & ROI

PROCESS

PYROCY’s modular micro-refineries operate in oxygen-free conditions, cracking polymers into oil, syngas, and carbon black. Systems are designed for minimal operator intervention with integrated safety and advanced control.

Off-gas is recycled to provide process energy, reducing external fuel demand and lowering emissions. Optional post-treatment or distillation modules further upgrade the oil into tailored product cuts for specific offtakers.

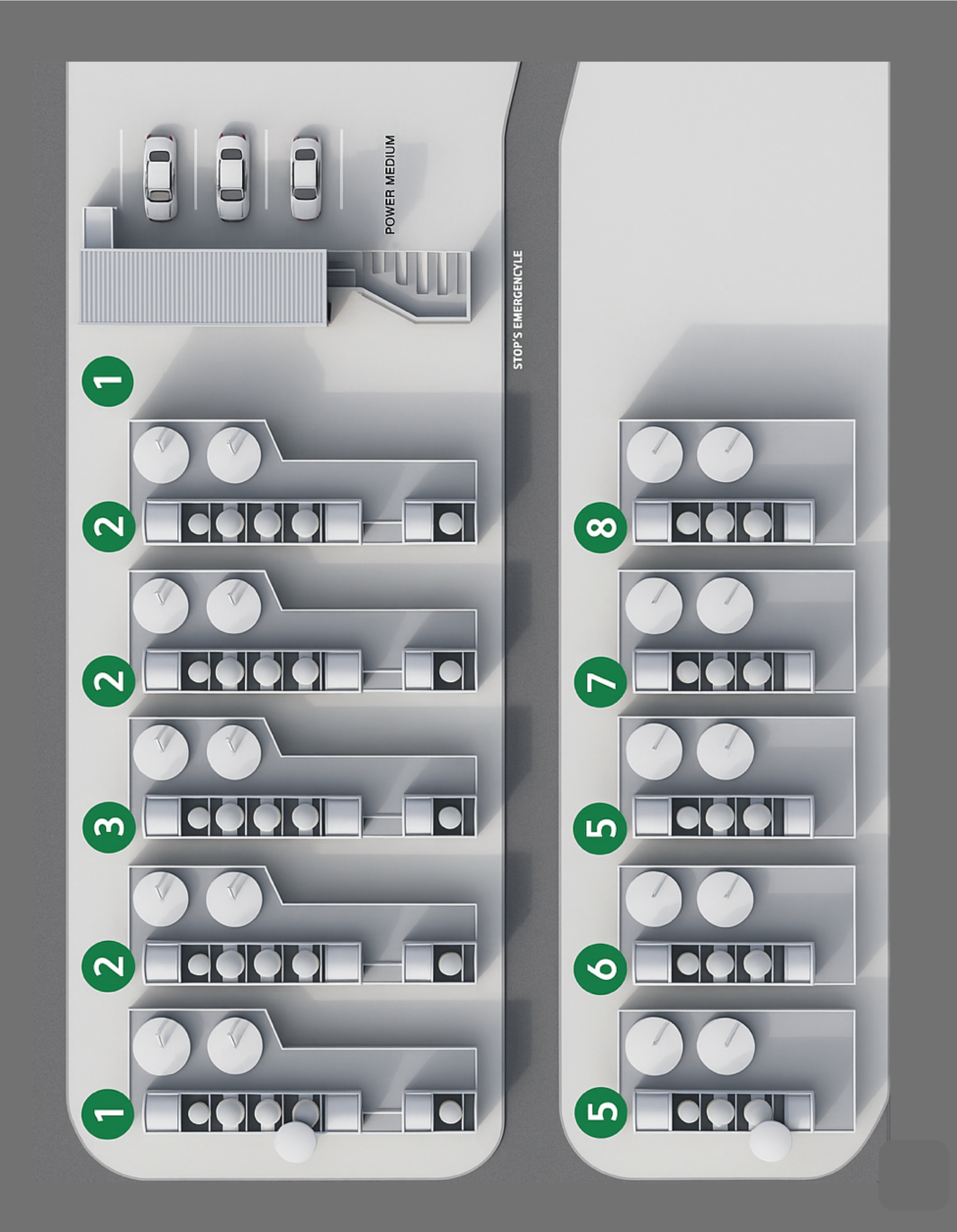

SCALABLE LAYOUTS (From 15TPD Units to 120TPD Clusters) Standard lines are configured as modular trains, which can be replicated across a site to match local feedstock availability and offtake contracts.

15–30TPD base modules for early-stage or pilot projects

60–120TPD multi-line layouts for full commercial plants

Skid-mounted design enables phased expansion and relocation

BUSINESS MODEL

Technology Sale to Long-Term Support

The waste-to-fuel sector is fragmented, with many suppliers offering isolated components. PYROCY provides a one-stop approach covering engineering, manufacturing, automation, commissioning, and ongoing operations support.

Commissioning, training, and SCADA/automation integration

Technology + operations support (O&M services)

Optional joint ventures or cost-plus-equity structures

SUSTAINABLE

IMPACT

PYROCY technology contributes directly to reducing waste volumes, lowering emissions and creating new energy pathways. By converting waste into resources, we support environmental responsibility while enabling economically viable projects.

PYROCY is actively developing and supporting projects across Europe, the Middle East, Africa, and Latin America, building a network of modular circular-fuel micro-refineries close to waste streams and offtakers.

Each project is designed around local feedstock, offtake agreements, and regulatory regimes, with a consistent technology and modular backbone.

1

Project Evaluation

2

System Design

Tailored plant configuration and capacity definition.

3

Deployment

Installation and commissioning support.

4

Operation & Optimization

Performance monitoring and continuous improvement.

OF CIRCULAR ENERGY

Whether you are exploring waste-to-energy opportunities or scaling an existing project, PYROCY is ready to support your initiative with proven pyrolysis technology.